Wire sawing for concrete is a method of cutting that not many people know about. In this blog we will answer questions like; what is concrete wire sawing and how a diamond wire saw works, as well as unfold some of the applications.

Diamond wire saws in Australia are common practice in the concrete and construction industry because they are so incredibly versatile and efficient at cutting concrete. However, they are underused in other industries and projects, so if you are a project manager, wire sawing is definitely something you should consider.

This blog will explain to you why you should be considering wire cutting for your next project.

What is a diamond wire saw?

A diamond wire saw differs from traditional methods of wire cutting, such as the bandsaw, by using friction from a wire running at speed to grind through material.

Why diamond? Because diamond is one of the hardest materials on the planet and is an effective method for cutting through any material that’s softer than it, which is practically everything.

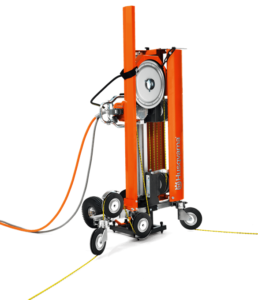

The wire used on an industrial wire saw is typically made from a loop of high tensile steel or synthetic rubber (as seen on Husqvarna) that is connected by a mechanical joiner. On the outside, the cable is impregnated with diamond beads and is coated with an elastomeric compound to help retain the diamond and protect it against corrosion. A wire can consist of one strand or multiple strands braided together to form a single cable.

How does a diamond wire saw work?

Wire saws are most comparable in principle to that of a reciprocating saw or bandsaw. The Diamond wire is placed around a material that needs to be cut, or threaded through a bore hole, and is then run at speed to utilise abrasion to effectively cut through slab or reinforced steel.

This method can produce a lot of heat and needs cooling so it can be used. The cooling method typically has a constant flow of water, oil or specialised cutting fluid to constantly lubricate the wire.

View how one of the Husqvarna wire saws work here.

Why use a diamond wire saw?

The reason why most turn to diamond wire cutting is for its ability to cut through just about any material faster and more efficiently than traditional methods of cutting. It produces far less waste when compared to conventional teeth-like blades, which can amount to significant savings especially when cutting expensive materials.

Depending on the type of machine being used, wire sawing is relatively clean, fumeless and quiet, with little to no vibrations, making it suitable for sensitive work environments such as a hospital. It’s also four to five times faster than conventional cutting methods and requires minimal manpower to operate.

Applications for wire sawing

Diamond sawing is an effective concrete cutting method that is ideal for removing large heavily reinforced, thick sections of concrete and other various applications:

- Demolition projects

- Dismantling large steel structures e.g. decommissioning mine sites

- Ideal for cutting thick/reinforced concrete structures: bridges, dams, factory floors, jetties, columns or beams

- Making angular cuts to vertical and horizontal structures

- Performing cuts in restricted, confined and sensitive areas

- Cut through heavy rebar and embedded steel

- Cut circular openings

- Extreme applications can include; subsea cutting of pipelines, conductors and other various underwater structures

Does your project require diamond wire saw cutting?

If you’re unsure about whether your project needs a wire saw, but you sure as hell know that concrete needs to be cut or removed, don’t try to do it yourself unless you are certified. Contact the professionals at Diamond Cut Concrete today for your concrete wire sawing in Perth needs.

With over 25 years of experience in the construction industry, we are able to recommend the best method and machinery to deliver quick and cost-effective concrete cutting and removal services on time and on budget.

Our team of experienced operators use the latest in diamond impregnated cutting technology to effectively cut, alter and remove concrete, brick, steel or asphalt across a wide range of applications.

We cut straight, we cut safe and we cut on time.